Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

Vacuum Sealing Assembly for 60 mm dia Tube w/ KF-25 Vacuum Port & 1/4 Feedthrough - EQ-FL-60KF25-FT

Description

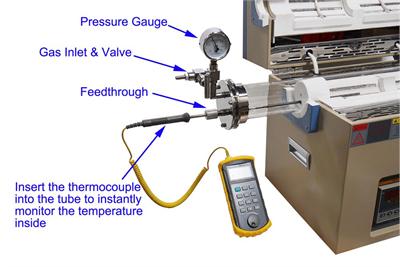

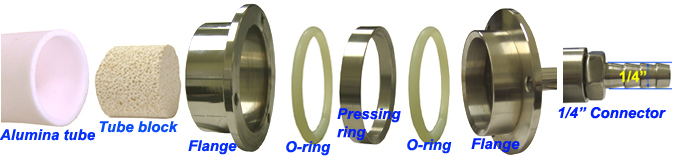

This is a pair of smart sealing assembly for 2" vacuum tube furnace to seal both ends of OD 60mm tube without any welding and gluing.

SPECIFICATIONS

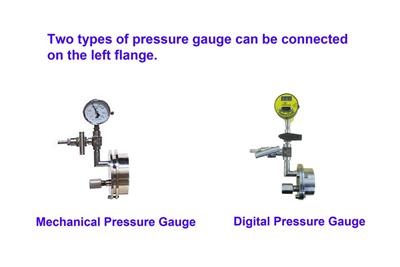

| Package included | One Mechanical Pressure Gauge ( Optional: Digital Pressure Gauge), two flanges, two steel sealing rings, four high-temperature silicone O-rings ( 300ºC Max.), and six screws |

| Structure | http://www.mtixtl.com/images/products/thumb/50mmflangemain.jpg" alt="" width="99" height="66" style="border: 0px;" title="Click to enlarge" />  http://www.mtixtl.com/images/products/thumb/50mmflangerightbig.jpg" alt="" width="102" height="68" style="border: 0px;" title="Click to enlarge" /> http://www.mtixtl.com/images/products/thumb/50mmflangerightbig.jpg" alt="" width="102" height="68" style="border: 0px;" title="Click to enlarge" />   |

| Features |

|

| Descriptions |

|

| Installation Video |  |

| Dimensions |  Click to enlarge Click to enlarge |

| Warning |

|