Furnace Structure | - Double-layer steel casing.

- High purity 1800oC grade fibrous alumina insulation

- Alumina processing tube, vacuum & gas sealing flange with valves, vacuum gauge, thermal blocks are included for immediate use

|

Power Consumption | Max. 4 KW |

Input Voltage | Single Phase, 220V AC, 50/60 Hz |

Normal Working Temperature: | 800-1600 oC |

Max. Working Temperature: | 1700 oC (3092 oF) for < 1 hours |

Max. Heating / Cooling Rate: | 5 oC / min above 1200 oC and 10 oC/min below 1200oC |

Heating Zone

| - Heating zone length: 200mm

- Constant temperature zone: 70mm within +/-1ºC

|

Heating Elements | 4 pcs of U-shaped 1800 grade MoSi2 |

Processing Tube  | - Tube Size: ID: 74mm; OD: 80 mm x Length 1000 mm

- 99.5 %High purity Al2O3 Ceramic.

Two fibrous ceramic tube blocks are included for blocking heat radiation from the inside tube. (Ceramic blocks must be fully inserted into the furnace chamber before heating)

|

Temperature Controller

| - FA-YD518P-AG temperature controller is included.

- Proportional–integral–derivative control (PID control) and auto-tune function

- 30 segments programmed with ramping, cooling and dwelling steps

- Built-in over-temperature alarm and thermocouple failure alarm

- +/- 1 ºC temperature control accuracy

- Default DB9 PC communication port

- MET Certified

|

Temperature controller (optional)  | - MTS02-Y Temperature control software kit (for YD518P series controllers) + 15" laptop package is available at the options bar. Click for detailed information about the MTS02-Y software kit.

- You may upgrade the temperature controller to the Eurotherm 3504 Temperature Controller which is fully compatible with LabVIEW. This package includes a Eurotherm 3504 programmer, a communication cable (RS485 - USB), and a software CD. Click the pic below to view the full spec of the Eurotherm 3504 temperature controller.

|

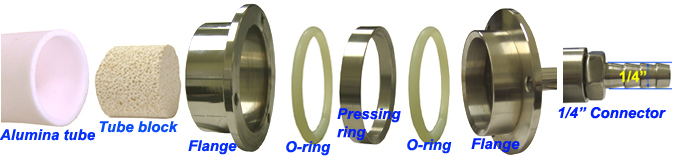

Vacuum Sealing Flanges | - One pair sealing flange with double silicone high-temperature O-ring is included.

- Two SS needle valves and one dial vacuum gauge are installed with flange for immediate use.

- Vacuum pressure can reach 50 mTorr by a quality mechanical vacuum pump and 10^-5 torr by a turbopump. Please click the picture below to see the flange assembling details.

|

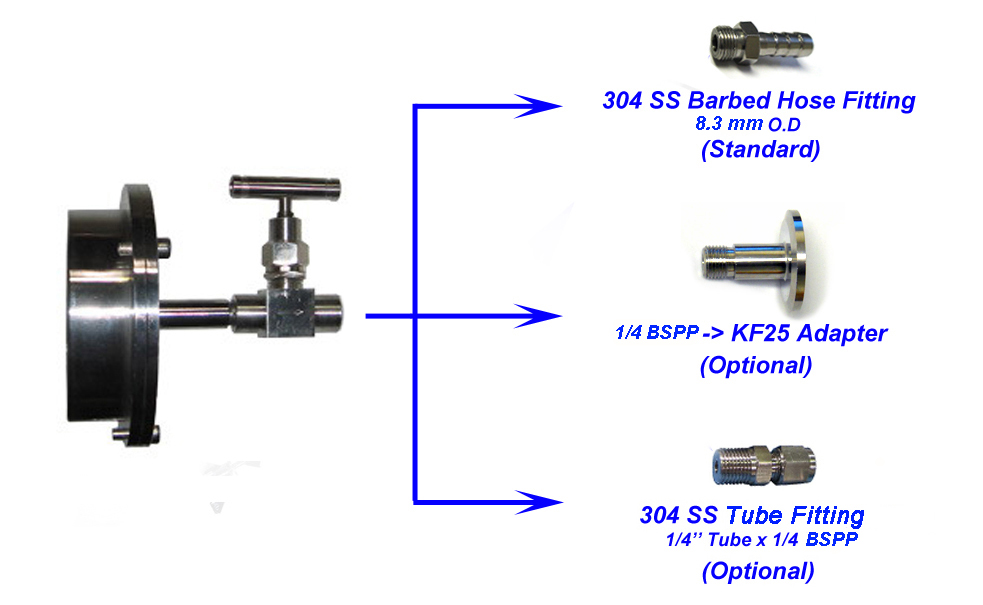

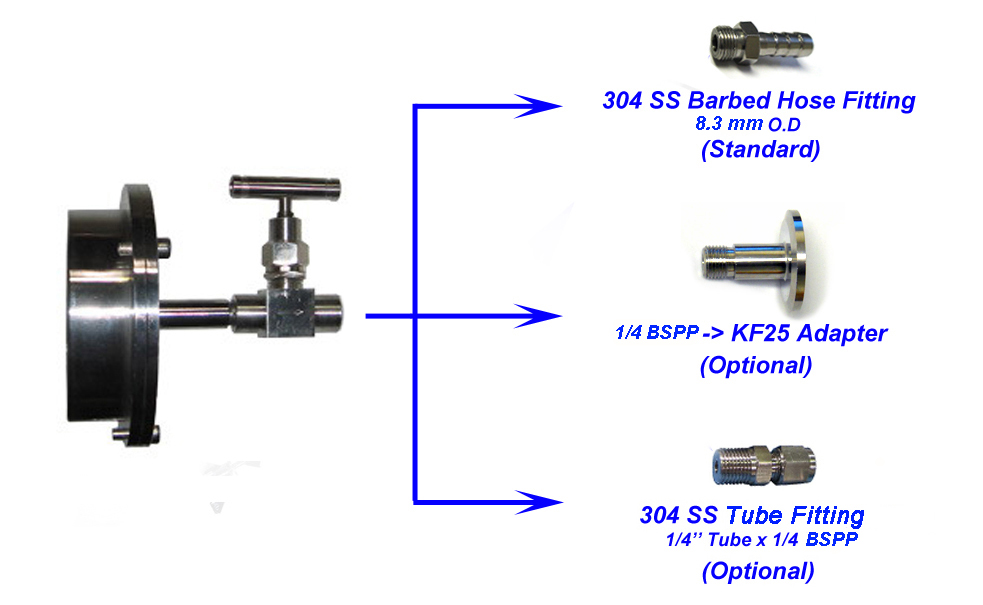

Fitting Ports

| - Standard 1/4‘’ Barbed fittings with needle valves.

- For supplying high-pressure gas, you may replace the standard barbed hose fitting with the 304SS 1/4" Swagelok® Tube Fitting, please click underlined to order.

- Optional: In order to increase the throughput and achieve high vacuum, you may replace the standard barbed hose fitting with the KF25 adapter, please click the underlined to order.

- Optional: You may also consider using the parts to upgrade the furnace

|

Vacuum Level | - Limited by the vacuum pump

- 50 m-torr can be achieved by the mechanical pump

- 10^-5 torr can be reached by the molecular pump

The vacuum pump is not included, please order separately by clicking the pictures The vacuum pump is not included, please order separately by clicking the pictures |

Power Cable & Plug | - 10 feet long 10-3 AWG heavy duty UL approved power cable is included. Extra length cable can be ordered by click picture below-left

- The plug is not included. Browse our catalog for compatible plugs or obtain one from a local hardware store.

|

Dimensions | Overall: 550 L x 550 W x 1250 H mm. |

Net Weight | 150 kg (330 lbs) |

Shipping Dimensions | 48" x 40" x 75" |

Shipping Weight | 510 lbs |

Warranty | One-year limited warranty (Consumable parts such as processing tubes, O-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Laptop, software & WiFi Control (Optional) | - Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial) for immediate use.

- Labview Based Temperature Control System (EQ-MTS01) enables the user to edit temperature profiles, manage heat-treatment recipe, record and plot data for MTI furnaces.

- A wireless remote control provides up to 300 meters of operating range.

- The above features are available upon request at an extra cost (up to $1,000).

-

|

Certificates | - CE Certified

- NRTL or CSA certification is available upon request at extra cost. ( please click marks below to learn details )

|

Warning | MoSi2 heating element is used in high temperatures under an oxidizing atmosphere. During the oxidizing process, the SiO2 protective film is formed again the heating element from melting during sustained use. The MoSi2 heating element must not be used in the temperature between 400 oC and 700 oC for a long time, otherwise, the element will be cremated under the strong oxidizing atmosphere at low temperatures. |

Application Notes

| |

Operation Instructions |

|