Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

ALD-150LE™ – Our most affordable ALD system designed specifically with entry to mid-level user in mind

Description

Overview

The Kurt J. Lesker Company® (KJLC®) ALD150LE™ is our most affordable, but extremely flexible Atomic Layer Deposition (ALD) system specifically designed with the entry to mid-level user in mind. The ALD150LE™ is configured for purely thermal ALD, and its unique process chamber design promotes uniform precursor dispersion and delivery. Superior heating and temperature control further enhance system performance. Overall, the ALD150LE™ provides unparalleled flexibility and performance in a compact design without sacrificing serviceability.

Technical Description

Process Chamber

- Purely thermal configuration

- Perpendicular flow design

- Two separate chamber inlets for precursor delivery

- Open-load (up to 150 mm substrates)

- Independent substrate heater stage

Precursors

- Up to 13 precursor sources with two separate chamber inlets

- Variety of precursor delivery options are available including vapor draw, flow-through and pulsed gas delivery

- Exposure modes include dynamic, static and Variable Residence Mode™

- Ozone source

Typical Processes

- Al2O3, TiO2, SiO2, Ta2O5, HfO2, ZrO2, HZO, ZnO, AZO, AIN, TiN, GaN, Pt, and Ru

Overview

The Kurt J. Lesker Company® (KJLC®) ALD150LE™ is our most affordable, but extremely flexible Atomic Layer Deposition (ALD) system specifically designed with the entry to mid-level user in mind. The ALD150LE™ is configured for purely thermal ALD, and its unique process chamber design promotes uniform precursor dispersion and delivery. Superior heating and temperature control further enhance system performance. Overall, the ALD150LE™ provides unparalleled flexibility and performance in a compact design without sacrificing serviceability.

Technical Description

Process Chamber

- Purely thermal configuration

- Perpendicular flow design

- Two separate chamber inlets for precursor delivery

- Open-load (up to 150 mm substrates)

- Independent substrate heater stage

Precursors

- Up to 13 precursor sources with two separate chamber inlets

- Variety of precursor delivery options are available including vapor draw, flow-through and pulsed gas delivery

- Exposure modes include dynamic, static and Variable Residence Mode™

- Ozone source

Typical Processes

- Al2O3, TiO2, SiO2, Ta2O5, HfO2, ZrO2, HZO, ZnO, AZO, AIN, TiN, GaN, Pt, and Ru

System Heating

- Independent substrate heater stage capable of up to 500°C operation

- Process chamber and precursor delivery line heating up to 250°C

- Precursor heating up to 200°C

- Delivery Line heating up to 250°C

- Up to 200°C Valve Heating

Software & Controls

- KJLC® eKLipse™ system control software (LabView based)

- Real time controller

- True precision ALD valve timing

Process Pump

- Rotary vane pump (>14 cfm) with foreline purge/vent protection and oil filtration

- Dry pump

- Customer supplied process pump

Substrate Transfer

- Manual loading

- Glove Box

Features

The ALD150LE™ is configured for purely thermal ALD, and our unique perpendicular flow design enables isolated, uniform precursor delivery with reduced background impurity levels for improved film quality. To avoid unwanted material buildup and particulate formation inside delivery channels, two separate chamber inlets are available for precursor isolation. For example, separate inlets can be used to isolate metal organic precursors and co-reactants to prevent deposition in delivery lines and valves.

- Two separate inlets for precursor delivery to prevent unwanted buildup in delivery channels

- Open-load chamber engineered to minimize background impurities due to seal outgassing and permeation

- Independent substrate heater stage and outer chamber casing for excellent temperature control and uniformity

- 304L stainless-steel construction

- Accessible, low maintenance design

The ALD150LE™ open-load design enables manual placement of substrates (up to 150 mm in diameter) directly onto the substrate heater stage during sample introduction. During subsequent ALD processing, centralized precursor delivery and pumping sets up a barrier that keeps impurities from downstream chamber seals out of the reaction zone. The strategic positioning of elastomer chamber seals downstream keeps impurities (due to seal outgassing and permeation) away from substrate surfaces for improved ALD film quality. In particular, this is an important feature for obtaining high quality nitride films in an open-load chamber design.

Precursor Delivery

The base ALD150LE™ system includes two heated, single-source vapor draw modules with two separate chamber inlets (to avoid unwanted buildup in delivery line components), that operate in dynamic or static exposure modes. For the full range of precursor delivery options currently available, please refer to the Options Tab for more information.

Heating

The ALD150LE™ employs superior heating and temperature control that complements our unique perpendicular flow design by further enhancing overall system performance. In particular, temperature uniformity and control helps to prevent unwanted precursor condensation resulting in parasitic effects that reduce film quality and compromise chamber cleanliness.

Upper temperature Limits for heated system components are as follows:

- Substrate heater stage 500°C

- Chamber and precursor delivery lines 250°C

- Precursors and delivery valves 200°C

- Delivery Line heating up to 250°C

- Up to 200°C Valve Heating

Our unique heater design combined with independent heat zones for precursors, delivery valves and lines, process chamber (multiple zones), substrate heater as well as foreline components provide unparalleled temperature control and uniformity of heated system components.

Options

Precursor Delivery Options

With up to ten precursor sources that utilize four separate chamber inlets, the ALD150LE™ provides extreme process flexibility. Modules are available for gas, liquid and solid phase precursors with a host of delivery options including vapor draw, flow-through and pulsed gas delivery. A fully integrated ozone delivery option is also available. Please contact us for more information regarding our ozone option.

For delivery options that require heating, our unique heater designs combined with independent heat zones for precursors, delivery valves and lines provide unparalleled temperature control and uniformity. Excellent temperature uniformity and control helps to prevent unwanted precursor condensation resulting in parasitic effects that reduce film quality and compromise chamber cleanliness.

Precursor exposure modes include dynamic, static and Variable Residence Mode™. Dynamic and static modes are standard features; Variable Residence Mode™ is optional. Please contact us for more information regarding our Variable Residence Mode™ option. The modular, scalable ALD150LE™ design accommodates a variety of different configurations including future expansion and upgrades.

Single-Source & Multi-Source Vapor Draw Modules

Vapor draw sources are ideal for liquid and solid phase precursors with sufficient vapor pressure such that they do not require any special assistance for effective vapor delivery other than heating. The base ALD150LE™ system includes two heated, single-source vapor draw modules with two separate chamber inlets (standard feature).

- Optional multi-source vapor draw module (replaces one of the base single-source modules)

- Multi-source vapor draw module can include up to five vapor draw sources

- Precursor and delivery valve heating are independently controlled up to 200°C

- Delivery lines are independently controlled to 250°C

- Vapor draw modules feature true precision ALD valve timing for optimal precursor dose control

Flow-Through Vapor Delivery Module

For liquid and solid phase precursors with insufficient/low vapor pressure, flow-through sources provide enhanced vapor delivery. Our unique, modular flow-through design provides added flexibility for advanced low vapor pressure delivery and supports both flow-through and vapor draw methods. The ALD150LE™ can accommodate up to two flow-through modules.

- Fully enclosed oven or independently heated precursor cylinder configurations

- Precursor and delivery valve heating independently controlled up to 200°C (oven configuration not fully independent)

- Delivery line heating independently controlled to 250°C

- True precision ALD valve timing for optimal precursor dose control

Pulsed Gas Delivery

Pulsed gas options include our Pulsed Gas Source™ (PGS™) delivery module specifically designed for precise, accurate, high-speed dosing of toxic gases (e.g., WF6, HCl, NH3, H2S, etc.). The KJLC® unique PGS™ design utilizes a fixed charge volume (or reservoir) for precursor dosing that eliminates the he need for a mass flow controller for precise, accurate delivery. To control the amount of precursor being delivered, precision ALD valve timing as well as reservoir pressure, are tightly controlled through our eKLipse™ software and controls package to enable high-speed dosing with both precision and accuracy. The ALD150LE™ can accommodate one PGS™ module.

- Designed specifically for precise, accurate high-speed dosing of toxic gases (e.g., WF6, HCl, NH3, H2S, etc.)

- Eliminates the need for mass flow controllers

- Includes separate channel for pumping and purging of input line components

Substrate Transfer Options

Up to 150 mm diameter substrates are introduced manually in atmosphere (standard), or within a glove box enclosure to provide a clean, inactive environment for handling (optional).

Standard:

- Manual loading

Optional:

- Glove box

Pumping & Pressure Measurement

The standard pump for the ALD150LE™ is an Adixen™ (Pfeiffer®) Chemical Pascal Series 2021C1 (13 cfm, Hydrocarbon Oil) rotary vane pump with optional foreline purge/vent protection and oil filtration. The standard pump can also be upgraded to a 2021C2 (13 cfm, PFPE prepared) rotary vane pump with optional foreline purge/vent protection and oil filtration. A dry pump with foreline purge/vent protection, as well as a customer supplied pump are also optional. A heated (150°C) capacitance manometer measures process chamber pressure.

Standard:

- Adixen™ (Pfeiffer®) Chemical Pascal Series 2021C1 (13 cfm, Hydrocarbon Oil) rotary vane pump

- Heated (150°C) capacitance manometer measures process chamber pressure

Optional:

- Adixen™ (Pfeiffer®) Chemical Pascal Series 2021C2 (13 cfm, PFPE prepped) rotary vane pump

- Foreline purge/vent protection

- Oil filtration

- Dry pump (optional) with foreline purge/vent protection

- Customer supplied pump

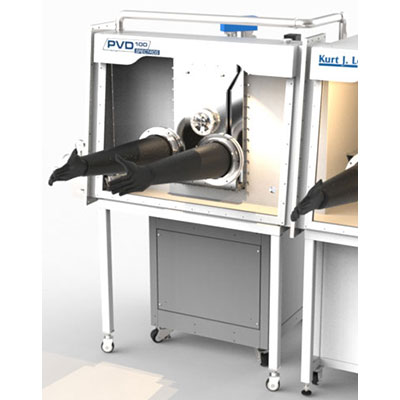

Glovebox Adaptors

The ALD-150LE™ and ALD-150LX™ are now easily integrated with a glove box. The process chamber is strategically positioned in the glovebox to provide the user with easy access to load and unload their substrate.

Kurt J Lesker is able to offer a wide array of standard and custom glovebox suites, from a standard 4 port or 6 port arrangement, to custom lengths and depths.

Glovebox Specifications

- All stainless steel construction of the glovebox

- Specifically designed to integrate with KJL deposition system

- All stainless steel Swagelok valves, fittings and piping

- Modular design (for easy expansion)

- Lexan front window

- Quick release front window

- Electrical feedthrough with a six (6) outlet power strip

- LED light fixtures

- All stainless steel antechamber; size 15" diameter x 24"L with sliding tray

- Shock assisted door lifting mechanisms

- All stainless steel mini antechamber; size 8" diameter x 15"L

- Stainless steel stand with leveling feet and casters

- Stainless steel vacuum gauges

- Adjustable bin storage unit (adjustable shelving)

- Spare KF40 feedthroughs

- Two (2) HEPA gas flow filters; one (1) inlet, one (1) outlet

- Push button evacuation and refill of antechamber

- All stainless steel 24V DC solenoid valve for refill of antechamber

- Automatic electro-pneumatic valve for evacuation of the antechamber (KF40)

- Common vent line

- Stainless steel filter column for the removal of oxygen and moisture including automatic electro-pneumatic valves (KF40 size)

- Fully automatic system with Siemens PLC control unit and 7" color touch screen with built in operating instructions and system diagnostics. Includes:

- O2, H20 and pressure trending

- Maintenance alarms

- Power saver mode for vacuum pump/lights (optional)

- Automatic regeneration process using 3-5% hydrogen gas mixture

- Capable of removing 36 liters of oxygen from inert gas before needing a regeneration

- Capable of removing 1300 grams of moisture from inert gas before needing a regeneration

- Continuous oxygen monitoring

- Continuous moisture monitoring

- Includes 50 cfm circulation blower

- Built for continuous operation

- Manual solvent removal system including stainless steel filter column, 10lbs of activated carbon, manual bypass and isolation valves, evacuation and refill valves, and refill drain port (optional)

- Automatic solvent removal system including stainless steel filter column with 20lbs of molecular sieve, automatic bypass and isolation valves with automatic reactivation of filter material (optional)

- Automatic purge valve-200 L/min flow rate

Glovebox Options

Along with the gloveboxes and system adaptor boxes the following accessories can be supplied:

- Spin Coaters

- Hot Plates

- UV Ozone Curing

- Regenerable Solvent Purification System

- Other accessories upon request