Phone(+65) 6284 3818 | sales@premier-sols.com | Enquriy |

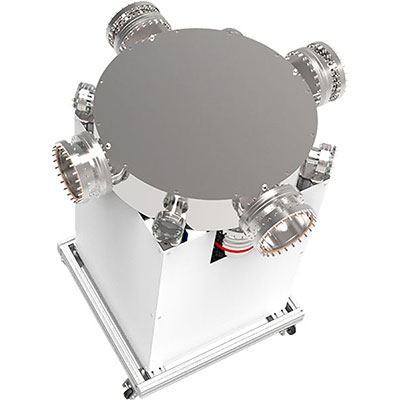

OCTOS™ – Automated Thin Film Deposition Cluster Tool

Description

Overview

The Kurt J. Lesker Company® OCTOS cluster tools are proven R&D and pilot production systems for in vacuum transfer between multiple process chambers.

Typical applications include Magnetic Tunnel Junctions and Spin Logic devices (GMR, TMR, MRAM, STT), Organic Light Emitting Devices (OLED), Solar Cells (PV, OPV).

The OCTOS cluster tools feature single or multiple substrate cassette load locks and allow process recipe steps to be completed in vacuum without exposing the substrate to atmosphere. OCTOS provides the ability to automatically process substrates sequentially one at a time or in parallel to increase throughput. Substrate tracking ability is available and full process datalogging is standard.

Process chambers are arranged around a central robotic distribution chamber to suit your application.

KJLC's eKLipse software allows user-friendly recipe creation along with a reliable, uninterruptable controller that allows process completion, regardless of the state of the computer user interface. For more information on this intuitive, unique, and reliable software package, please see the Software Tab.

KJLC has been manufacturing the OCTOS cluster tool platform since 1999. Most of our OCTOS cluster tools have become workhorses for their owners and are still in daily use, including one that has processed over a million substrates.

Techniques Offered:

- Electron Beam Evaporation

- Thermal Evaporation

- Magnetron Sputtering

- Organic Evaporation

- Atomic Layer Deposition

Options:

- HV or UHV Process Modules

- Plasma Cleaning

- Substrate Annealing

- Mask Storage and in-situ Mask Changing

- Glove Box Integration

- Custom Process Modules

- Transfer to in-vacuum analysis chambers such as XPS

- Integration with third party process chambers like PLD or CVD

Substrate Handling

Two OCTOS robotic substrate distribution chambers are offered: OCTOS 6 and OCTOS 10. Both use industry standard vacuum compatible robots. The OCTOS chambers are available with turbomolecular or cryogenic pumping packages to fit your needs.

Robot transferring samples.

OCTOS 6 Substrate Distribution Chamber

- R&D robotic distribution chamber

- Standard substrate sizes up to 6" (150mm) diameter

- Uses Genmark AVR Robot with 5 lb. Payload, > 80,000 hours MTBF

- Maximum of six process modules including single and multiple substrate cassette load locks. The number of potential process chambers is limited by substrate and process module size

- Computer controlled using KJLC eKLipse software

OCTOS 10 Substrate Distribution Chamber

- R&D or Pilot Production capable

- Standard substrate sizes up to 8" x 8" (200mm x 200mm)

- Uses Genmark GB-9 Robot with 25lb payload, > 80,000 hours MTBF

- Maximum of ten process modules including single and multiple substrate cassette load locks. The number of potential process chambers is limited by substrate and process module size

- Computer controlled using KJLC eKLipse software