Battery Fabrication

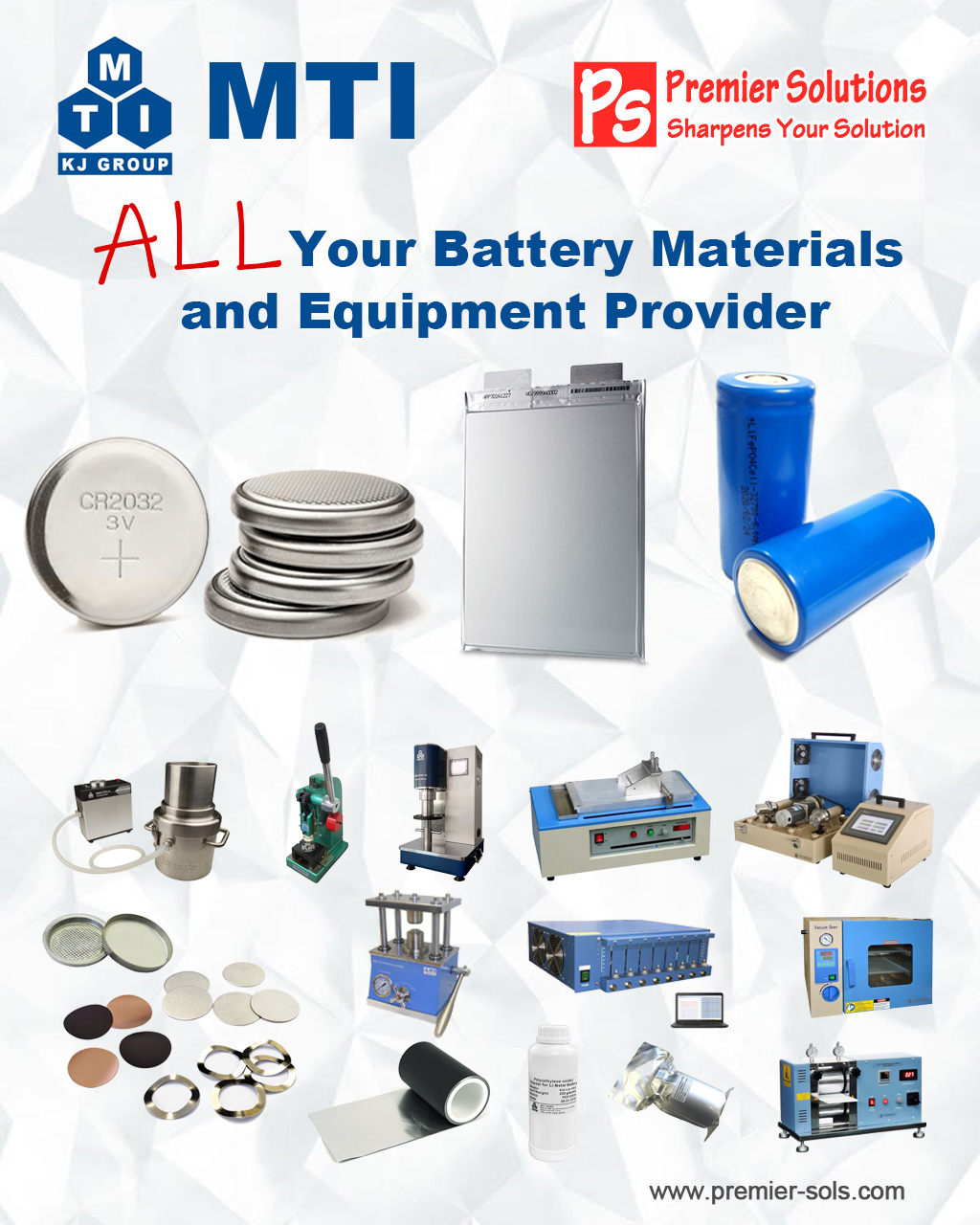

Coin Cell | Pouch Cell | Cylindrical Cell R&D

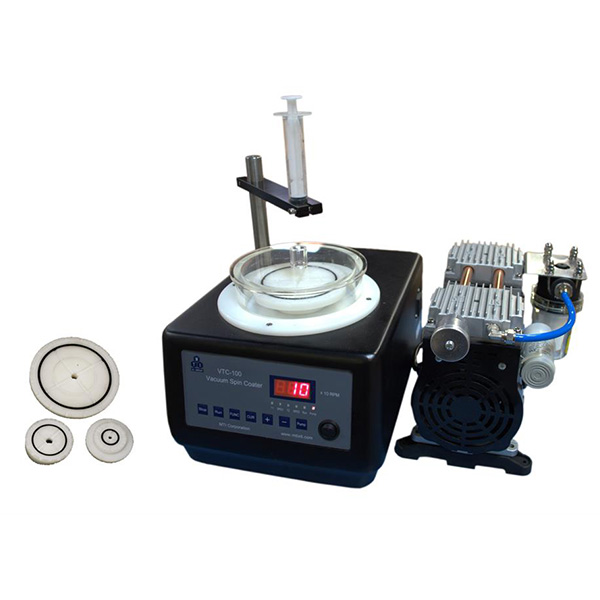

Equipment plays a critical role in determining the performance and cost of lithium-ion batteries. Mirroring the three manufacturing stages, equipment can be divided into three categories as well: the 1st stage equipment (Mixer, Coater, Roller Press, Splitting Machine, Filming Machine, Die-cutting Machine, etc.), the 2nd stage equipment (Winding/lamination machine, electrolyte injection machine, packaging equipment), and the 3rd stage equipment (Charging and discharging machines, testing equipment, etc.). The capital cost for each of these three stages represents approximately 40%, 30%, 30% of the cost of the production line.

Therefore, the selection of good equipment is very important in the battery fabrication process.

Coin Cell Fabrication

Coin cells are widely used in research laboratories to test new battery materials; even for the research and development that target large-scale and high-power applications, small coin cells are often used to test the capacities and rate capabilities of new materials in the initial stage.

Premier Solutions provide complete solutions for coin cell battery preparation.

Coin Cell Assembly Steps Video

The video show about how to make high-quality coin cells.

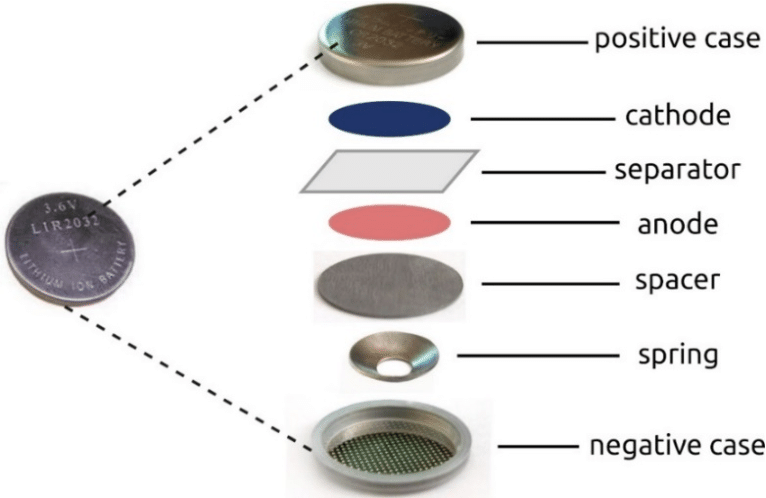

Assemble the coin cells: coin cell cases (CR2032), springs and spacers (purchased from MTI Corp.), separators and working electrodes.

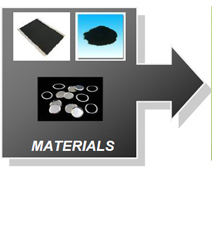

Coin Cell Materials contains seven components including the cathode and anode caps of the cell case, a stainless steel spring, stainless steel spacer, lithium manganese oxide cathode with steel mesh current collector, glass fiber separator, and a graphite anode with steel mesh current collector. Their anode is generally composed of zinc or lithium and their cathode is made up of manganese dioxide, silver oxide, carbon monofluoride, copper oxide, or dioxygen drawn from the air. Lithium coin cell batteries with the positive electrode of manganese dioxide have an organic electrolyte.

Coin Cell Materials contains seven components including the cathode and anode caps of the cell case, a stainless steel spring, stainless steel spacer, lithium manganese oxide cathode with steel mesh current collector, glass fiber separator, and a graphite anode with steel mesh current collector. Their anode is generally composed of zinc or lithium and their cathode is made up of manganese dioxide, silver oxide, carbon monofluoride, copper oxide, or dioxygen drawn from the air. Lithium coin cell batteries with the positive electrode of manganese dioxide have an organic electrolyte.

Chemical Powders, Binders, and Electrodes |  Al. Cu, C, Li, SS Current Collector |

Cases of Coin/Cylinder / Pouch Cell |  Electrolyte for Li-Ion Battery ( Liquid & Solid) |

The various stages within the typical process steps in the production of Li-ion batteries are highly dependent on the quality of the slurry produced at the start of the process. The properties of the slurry will in turn depend on the properties of the powder mixed with the binder and solvents, and how it behaves in the mixing process.

The resulting slurry must meet critical criteria such as fineness of grain (FOG), viscosity and solid content to ensure optimal process performance as well as a high-quality final product. In particular, solid content uniformity influences how efficiently a slurry coats a substrate so the ability of the powder to mix and disperse, without agglomerating, is critical.

The various stages within the typical process steps in the production of Li-ion batteries are highly dependent on the quality of the slurry produced at the start of the process. The properties of the slurry will in turn depend on the properties of the powder mixed with the binder and solvents, and how it behaves in the mixing process.

The resulting slurry must meet critical criteria such as fineness of grain (FOG), viscosity and solid content to ensure optimal process performance as well as a high-quality final product. In particular, solid content uniformity influences how efficiently a slurry coats a substrate so the ability of the powder to mix and disperse, without agglomerating, is critical.

For optimum battery performance, it is important for the active materials in batteries to have well-defined particle size distribution and small particles. Ultra-fine milling of the active powders creates a smaller particle with a larger surface area. The result is a higher usable capacity, faster recharging and longer useful life.

The majority of today’s battery electrode slurries are composed of a carbon, graphite and binder, coated in a thin film onto a current collector (typically, an aluminum foil is used with the cathode, and a copper foil for the anode).

These thin films are then layered upon each other with a separator in between. The films can be stacked in a rectangular shape or wound together (see graphic). The current collectors at the edges or tips of these films are bonded together by tabs in a welding process, thus allowing like electrodes to be combined together.

Example of films wound together in a battery.

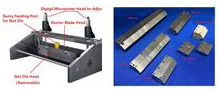

This methodology will likely not change with the advent of new battery technologies no matter what new materials are used in slurry. Thus the need to improve the coating process, and ultimately improve the quality of the layers, is paramount.

It is very important to choose the correct coating equipment!

Rolling press machine is used for lithium battery electrode calendering after coating or cutting. It can increase surface density by press the electrode. The rolling press machine also has some models according to it's rolling press width and rolling press mode.